Robotics - What is Robotics?

Roboticists develop man-made mechanical devices that can move by

themselves, whose motion must be modelled, planned, sensed, actuated

and controlled, and whose motion behaviour can be influenced by

“programming”. Robots are called “intelligent” if they succeed in

moving in safe interaction with an unstructured environment, while

autonomously achieving their specified tasks.

This definition implies that a device can only be called a “robot” if

it contains a movable mechanism, influenced by sensing, planning,

actuation and control components. It does not imply that a minimum

number of these components must be implemented in software, or be

changeable by the “consumer” who uses the device; for example, the

motion behaviour can have been hard-wired into the device by the

manufacturer.

So, the presented definition, as well as the rest of the material in

this part of the WEBook, covers not just “pure” robotics or only

“intelligent” robots, but rather the somewhat broader domain of

robotics and automation. This includes “dumb” robots such as: metal

and woodworking machines, “intelligent” washing machines, dish washers

and pool cleaning robots, etc. These examples all have sensing,

planning and control, but often not in individually separated

components. For example, the sensing and planning behaviour of the

pool cleaning robot have been integrated into the mechanical design of

the device, by the intelligence of the human developer.

Robotics is, to a very large extent, all about system integration,

achieving a task by an actuated mechanical device, via an

“intelligent” integration of components, many of which it shares with

other domains, such as systems and control, computer science,

character animation, machine design, computer vision, artificial

intelligence, cognitive science, biomechanics, etc. In addition, the

boundaries of robotics cannot be clearly defined, since also its

“core” ideas, concepts and algorithms are being applied in an ever

increasing number of “external” applications, and, vice versa, core

technology from other domains (vision, biology, cognitive science or

biomechanics, for example) are becoming crucial components in more and

more modern robotic systems.

This part of the WEBook makes an effort to define what exactly is that

above-mentioned core material of the robotics domain, and to describe

it in a consistent and motivated structure. Nevertheless, this chosen

structure is only one of the many possible “views” that one can want

to have on the robotics domain.

In the same vein, the above-mentioned “definition” of robotics is not

meant to be definitive or final, and it is only used as a rough

framework to structure the various chapters of the WEBook. (A later

phase in the WEBook development will allow different “semantic views”

on the WEBook material.)

Components of robotic systems

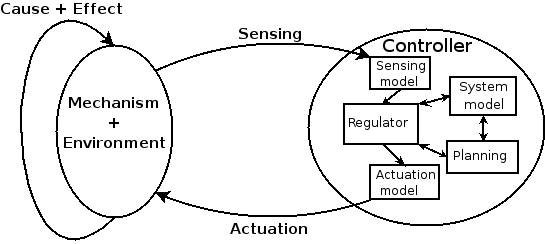

This figure depicts the components that are part of all robotic

systems. The purpose of this Section is to describe the semantics of

the terminology used to classify the chapters in the WEBook:

“sensing”, “planning”, “modelling”, “control”, etc.

The real robot is some mechanical device (“mechanism”) that moves

around in the environment, and, in doing so, physically interacts with

this environment. This interaction involves the exchange of physical

energy, in some form or another. Both the robot mechanism and the

environment can be the “cause” of the physical interaction through

“Actuation”, or experience the “effect” of the interaction, which can

be measured through “Sensing”.

Robotics as an integrated system of control interacting with the

physical world.

Sensing and actuation are the physical ports through which the

“Controller” of the robot determines the interaction of its mechanical

body with the physical world. As mentioned already before, the

controller can, in one extreme, consist of software only, but in the

other extreme everything can also be implemented in hardware.

Within the Controller component, several sub-activities are often

identified:

Modelling. The input-output relationships of all control components

can (but need not) be derived from information that is stored in a

model. This model can have many forms: analytical formulas, empirical

look-up tables, fuzzy rules, neural networks, etc.

The name “model” often gives rise to heated discussions among

different research “schools”, and the WEBook is not interested in

taking a stance in this debate: within the WEBook, “model” is to be

understood with its minimal semantics: “any information that is used

to determine or influence the input-output relationships of components

in the Controller.”

The other components discussed below can all have models inside. A

“System model” can be used to tie multiple components together, but it

is clear that not all robots use a System model. The “Sensing model”

and “Actuation model” contain the information with which to transform

raw physical data into task-dependent information for the controller,

and vice versa.

Planning. This is the activity that predicts the outcome of potential

actions, and selects the “best” one. Almost by definition, planning

can only be done on the basis of some sort of model.

Regulation. This component processes the outputs of the sensing and

planning components, to generate an actuation setpoint. Again, this

regulation activity could or could not rely on some sort of (system)

model.

The term “control” is often used instead of “regulation”, but it is

impossible to clearly identify the domains that use one term or the

other. The meaning used in the WEBook will be clear from the context.

Scales in robotic systems

The above-mentioned “components” description of a robotic system is to

be complemented by a “scale” description, i.e., the following system

scales have a large influence on the specific content of the planning,

sensing, modelling and control components at one particular scale, and

hence also on the corresponding sections of the WEBook.

Mechanical scale. The physical volume of the robot determines to a

large extent the limites of what can be done with it. Roughly

speaking, a large-scale robot (such as an autonomous container crane

or a space shuttle) has different capabilities and control problems

than a macro robot (such as an industrial robot arm), a desktop robot

(such as those “sumo” robots popular with hobbyists), or milli micro

or nano robots.

Spatial scale. There are large differences between robots that act in 1D, 2D, 3D, or 6D (three positions and three orientations).

Spatial scale. There are large differences between robots that act in 1D, 2D, 3D, or 6D (three positions and three orientations).

Time scale. There are large differences between robots that must react

within hours, seconds, milliseconds, or microseconds.

Power density scale. A robot must be actuated in order to move, but

actuators need space as well as energy, so the ratio between both

determines some capabilities of the robot.

System complexity scale. The complexity of a robot system increases

with the number of interactions between independent sub-systems, and

the control components must adapt to this complexity.

Computational complexity scale. Robot controllers are inevitably

running on real-world computing hardware, so they are constrained by

the available number of computations, the available communication

bandwidth, and the available memory storage.

Obviously, these scale parameters never apply completely independently

to the same system. For example, a system that must react at

microseconds time scale can not be of macro mechanical scale or

involve a high number of communication interactions with subsystems.

Background sensitivity

Finally, no description of even scientific material is ever fully

objective or context-free, in the sense that it is very difficult for

contributors to the WEBook to “forget” their background when writing

their contribution. In this respect, robotics has, roughly speaking,

two faces: (i) the mathematical and engineering face, which is quite

“standardized” in the sense that a large consensus exists about the

tools and theories to use (“systems theory”), and (ii) the AI face,

which is rather poorly standardized, not because of a lack of interest

or research efforts, but because of the inherent complexity of

“intelligent behaviour.” The terminology and systems-thinking of both

backgrounds are significantly different, hence the WEBook will

accomodate sections on the same material but written from various

perspectives. This is not a “bug”, but a “feature”: having the

different views in the context of the same WEBook can only lead to a

better mutual understanding and respect.

Research in engineering robotics follows the bottom-up approach:

existing and working systems are extended and made more versatile.

Research in artificial intelligence robotics is top-down: assuming

that a set of low-level primitives is available, how could one apply

them in order to increase the “intelligence” of a system. The border

between both approaches shifts continuously, as more and more

“intelligence” is cast into algorithmic, system-theoretic form. For

example, the response of a robot to sensor input was considered

“intelligent behaviour” in the late seventies and even early eighties.

Hence, it belonged to A.I. Later it was shown that many sensor-based

tasks such as surface following or visual tracking could be formulated

as control problems with algorithmic solutions. From then on, they did

not belong to A.I. any more.........

No comments:

Post a Comment